偏心對夾蝶閥適用于給排水、污水、建筑、空調、石油、化工、食品、醫藥、輕紡、造紙,水電、船舶、冶金、能源系統等,流體管線上作為調節和截流裝置來使用。是取代中壓閘閥、截止閥、球閥、旋塞閥的理想產品,是目前唯一能實現無磨損零泄漏,使用壽命長,并能承受一定反向壓力的高性能優秀產品。

執行機構選型| 公稱壓力 Nominal pressure |

0.6MPa | 1.0MPa | 1.6MPa | 2.5MPa |

|---|---|---|---|---|

| 公稱通徑 Nominal diameter |

80~3000 mm |

80~3000 mm |

80~2000 mm |

80~1200 mm |

| 密封試驗 Seal test |

0.66MPa | 1.1MPa | 1.76MPa | 2.75MPa |

| 殼體強度試驗 Shell strength tes |

0.9MPa | 1.5MPa | 2.4MPa | 3.75MPa |

| 適用溫度 Applicable temperature |

≤100℃~600℃ | |||

| 適用介質 Applicable medium |

煙氣、熱水、蒸汽、煤氣、酸、堿、食品 Flue gas, hot water, steam,gas, acld, alkall,food | |||

| 驅動形式 Driving form |

蝸輪傳動、電動、氣動 Worm gear drive,electric,pneumatic |

|||

| 閥體 valve body |

鑄鋼、不銹鋼、球墨鑄鐵 Cast steel, stainless steel, ductile cast iron |

|---|---|

| 閥座 valve seat |

不銹鋼 stainless steel |

| 蝶板 Disc |

鑄鋼、不銹鋼、球墨鑄鐵 Cast steel, stainless steel, ductile cast iron |

| 密封圈 sealring |

不銹鋼、橡膠 Stainless steel, rubber |

| 閥桿 stem |

2Cr13不銹鋼、1Cr13不銹鋼、45#鋼 2Cr13 stainless steel,1Cr13 stainless steel, 45#steel |

| 襯套 bushing |

鑄鉬青銅自潤軸承 Cast molybdenum bronze self lubrication bearing |

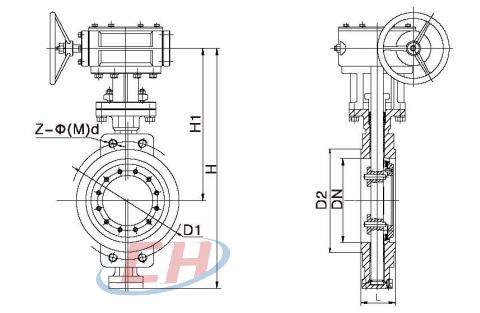

| 通徑 | 主要尺寸 | 0.6MPa | 1.0MPa | 1.6MPa | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| DN | L(短) | L(長) | H | H1 | D1 | D2 | Z-φ(M)d | D1 | D2 | Z-φ(M)d | D1 | D2 | Z-φ(M)d |

| 50 | 43 | 43 | 272 | 200 | 110 | 90 | 4-14 | 125 | 100 | 4-18 | 125 | 100 | 4-18 |

| 65 | 46 | 46 | 335 | 225 | 130 | 110 | 4-14 | 145 | 120 | 4-18 | 145 | 120 | 4-18 |

| 80 | 49 | 64 | 355 | 240 | 150 | 125 | 4-18 | 160 | 135 | 4-18 | 160 | 135 | 4-18 |

| 100 | 56 | 64 | 385 | 255 | 170 | 145 | 4-18 | 180 | 155 | 4-18 | 180 | 155 | 4-18 |

| 125 | 64 | 70 | 455 | 305 | 200 | 175 | 4-18 | 210 | 185 | 4-18 | 210 | 185 | 4-18 |

| 150 | 70 | 76 | 490 | 325 | 225 | 200 | 4-18 | 240 | 210 | 4-22 | 240 | 210 | 4-22 |

| 200 | 71 | 89 | 590 | 380 | 280 | 255 | 4-18 | 295 | 265 | 4-22 | 295 | 265 | 4-22 |

| 250 | 76 | 114 | 655 | 410 | 335 | 310 | 4-18 | 350 | 320 | 4-22 | 355 | 320 | 4-26 |

| 300 | 83 | 114 | 740 | 460 | 395 | 362 | 4-22 | 400 | 368 | 4-22 | 410 | 375 | 4-26 |

| 350 | 92 | 127 | 840 | 525 | 445 | 412 | 4-22 | 460 | 428 | 4-M20 | 470 | 435 | 4-M24 |

| 400 | 102 | 140 | 890 | 545 | 495 | 462 | 4-M20 | 515 | 482 | 4-M24 | 525 | 485 | 4-M27 |

| 450 | 114 | 152 | 1010 | 630 | 550 | 518 | 4-M20 | 565 | 532 | 4-M24 | 585 | 545 | 4-M27 |

| 500 | 127 | 152 | 1065 | 650 | 600 | 568 | 4-M20 | 620 | 585 | 4-M24 | 650 | 608 | 4-M30 |

| 600 | 154 | 178 | 1140 | 680 | 705 | 670 | 4-M24 | 725 | 685 | 4-M27 | 775 | 718 | 4-M33 |

| 700 | 165 | 229 | 1268 | 780 | 810 | 775 | 4-M24 | 840 | 800 | 4-M27 | 840 | 788 | 4-M33 |

| 800 | 190 | 241 | 1432 | 860 | 920 | 880 | 4-M27 | 950 | 905 | 4-M30 | 950 | 898 | 4-M36 |

| 900 | 203 | 241 | 1528 | 900 | 1020 | 980 | 4-M27 | 1050 | 1005 | 4-M30 | 1050 | 998 | 4-M36 |

| 1000 | 216 | 300 | 1698 | 1000 | 1120 | 1080 | 4-M27 | 1160 | 1115 | 4-M33 | 1170 | 1110 | 4-M39 |

| 1200 | 254 | 360 | 1910 | 1100 | 1340 | 1295 | 4-M30 | 1380 | 1325 | 4-M36 | 1390 | 1325 | 4-M45 |

| 1400 | 279 | 390 | 2140 | 1200 | 1560 | 1510 | 4-M33 | 1590 | 1530 | 4-M39 | 1590 | 1530 | 4-M45 |

| 1600 | 318 | 440 | 2420 | 1330 | 1760 | 1710 | 4-M33 | 1820 | 1760 | 4-M45 | 1820 | 1750 | 4-M52 |